CONTACT US

Data Comparison between Array Flexible Inclinometer and Manual Inclinometer

Here we share a comparision testing for data comparison between Array Flexible Inclinometer and Manual Inclinometer.

Location: in a monitoring project of foundation pit in Shenzhen University, Guangdong, China

1. Introduction of Comparison Testing Project

1.1 Introduction of Project

Deep foundation pit engineering is common in high-rise buildings and subway construction. Due to the complexity of engineering technology, the internal force and displacement of supporting structure and the internal and external deformation of foundation pit soil are often caused in the process of foundation pit excavation. If the deformation is not controlled properly, it will cause great potential safety hazards to the structural safety of foundation pit itself and surrounding structures. Deformation maintenance structure deep horizontal displacement monitoring, commonly known as inclines-measuring, is an important monitoring content in the process of foundation pit excavation. Deep displacement monitoring plays an important role in controlling the risk in the process of foundation pit excavation. In this report, we briefly compare and analyze the advantages and disadvantages of traditional manual inclinometer monitoring and automatic inclinometer monitoring in the deep displacement monitoring of foundation pit.

1.2 Monitoring Instrument and Accuracy of Instrument

(1) Manual inclinometer(INDEGEO-IN1000 Portable Inclinometer)

Technical parameter

Technical parameter of INDEGEO-IN1000 Digital Inclinometer MEMS Biaxial Probe:

Inclinometer sensor:double MEMS sensor Wheelbase:500mm

Measuring range:±30° Resolution:0.005mm

Repeatability:±0.003° Working Temperature:-40~70℃

Material:stainless steel Stabilization time of data: less than 1 second

(2) Automatic array flexible inclinometer(model:ADMV): Huasi array flexible inclinometer is a flexible and standard 3D measurement system. It uses a set of MEMS accelerometers array and a validated calculation program to measure 2D and 3D deformations. There is no priority axis with it. It can be bent freely and installed vertically, horizontally or circularly. Huasi array flexible inclinometer reflects the angular change of the corresponding axis and gravity direction by measuring the acceleration change of the accelerometer in different axes, and calculates the displacement change of the corresponding node through the angular change.

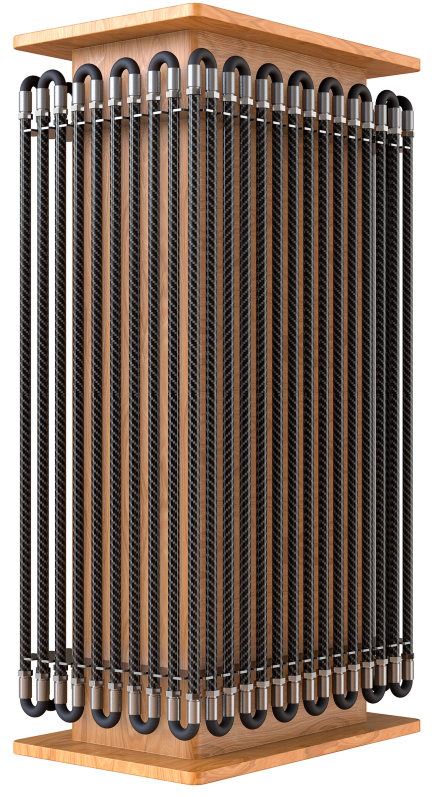

Appearance of array flexible inclinometer

Working principle

|

Technical Parameters of ADMV |

|

|

Technical Parameters |

ADMV |

|

Operation mode |

MEMS acceleration mode |

|

Measurement direction |

3 dimensions(X,Y,Z) |

|

Angle measurement |

0~360° |

|

Angle resolution |

±0.0003°(±1.08″) (±0.000005rad) |

|

Displacement resolution |

0.005mm@500mm |

|

System stability |

± 0.5mm(32m ) |

|

Measurement accuracy |

±0.002° (0.0006%F.S.) (0.02mm@500mm) |

|

Anti-twist accuracy |

± 1° |

|

Temperature measurement accuracy |

± 0.2℃ |

|

Temperature record |

Record real-time (every segment) |

|

Frequency for data collect |

1 second/time |

|

Power consumption |

DC12V 3.2mA/segment |

|

Maximum tensile |

550kgf |

|

Waterproof |

200m under water(2MPa) |

|

Operating temperature |

-40℃~60℃(humidity≤95%) |

|

Diameter |

18mm(main body), 25mm(maximum diameter) |

|

Magnetic field interference |

No interference |

|

Electric field interference |

No interference |

|

Deformation track |

Track real-time |

|

Length |

0.3m/0.5m/1m per segment, total length can be customized |

|

Maximum joint band angle |

180° |

|

Weight |

1kg/m(stainless steel material), 0.5kg/m(carbon fibre material) |

|

Communication cable |

Standard 10m(can be customized) |

|

Length of fiberglass extension |

2m |

|

Length of unsensorized near cable segment |

27.5cm |

|

Range of 3D model vertical |

0~180° |

2. Site Environment and Installation of Equipment

2.1 Testing environment

One week before the foundation pit excavation, the on-site construction team carried out the embedding of inclinometer casing and the collection of equipment initialization data. In order to ensure that the manual inclinometer and automatic inclinometer can measure the real change data of the foundation pit excavation process, the on-site construction team installed two inclinometer casing (i.e. two inclinometer casing are installed at the same measuring point), one for manual observation and the other for the installation of automatic inclinometer, The buried depth of inclinometer casing is 25m. The measuring guide groove of the manual inclinometer is perpendicular to the deformation direction of the excavation surface of the foundation pit. There is an offset angle of + 30 ° between the casing groove of the automatic inclinometer and the excavation surface of the foundation pit. The automatic inclinometer can correct the consistency of the measurement direction caused by the on-site installation error through the software algorithm.

2.2 Automatic array flexible inclinometer and installation

Array flexible inclinometer system has been tested overall before the installation. The array flexible inclinometer has been tested with the data logger and cloud platform to ensure that the cloud platform can normally receive and analyze the data of array flexible inclinometer

Move bundled the array flexible inclinometer near the inclinometer casing site, gradually unfold the array flexible inclinometer and drop it into the inclinometer casing. In the process of lowering the array flexible inclinometer, pay attention to the consistency between the X-Mark direction and the A direction of the inclinometer casing. Don’t bend and squeeze the array flexible inclinometer at the inclinometer casing orifice. It can be dropped by hand or reel.

Installation of instrument

Installation of instrument

3. Result of Testing Data Comparison

3.1 Testing period and frequency comparison

The collection time of the initial value of manual inclinometer is from January 4, 2021, and the collection frequency is once a day. By July 1, 113 times of data were collected. The maximum variation measured is 29.09mm at the position of 0.5m on the surface of the foundation pit.

The automatic inclinometer was installed on January 29, 2020. The data was taken as the initial data in the static state in the early morning of that night. The collection frequency was set to four times a day (once an hour in the early stage), the theoretical data was collected more than 600 times, the actual measured data of the platform was more than 3000, and the accuracy rate of the collected data was more than 95%.

3.2 Comparison of collected data

In this report, the inclination measurement data of array flexible inclinometer on a single day of each month will be selected from the project for nearly half a year, and compared with the manual inclinometer measurement data at the corresponding time. The data comparison between the two inclinometers is shown in the following figures.

According to the comparative analysis, the inclination measurement data of array flexible inclinometer is close to the manual inclinometer measurement data, and the displacement at the top of the foundation pit increases gradually with time. The overall change trend of the data shows an open deformation trend. It is necessary to focus on the corresponding changes of the foundation pit surface and surrounding soil and pipelines, and take measures to strengthen the maintenance of the foundation pit in time.

1)Comparison between array flexible inclinometer and manual inclinometer on February 17, 2021

(2)Comparison between array flexible inclinometer and manual inclinometer on March 17, 2021

(3)Comparison between array flexible inclinometer and manual inclinometer on April 18, 2021

(4)Comparison between array flexible inclinometer and manual inclinometer on May 17, 2021

(5)Comparison between array flexible inclinometer and manual inclinometer on June 13, 2021

(6)Comparison between array flexible inclinometer and manual inclinometer on June 23, 2021

4. Conclusion

4.1 The change trend of automatic inclinometer is highly consistent with that of manual inclinometer. The extension of on-site construction cycle and monitoring time shows that the data are highly coincident, which is in line with the comparative test effect. In February, March and April, the key period of foundation pit excavation, the deformation trend prediction of automatic inclinometer data is prior to the change response of manual inclinometer. When the later excavation is stable, the data curves in the data interval in May, June and July basically coincide. The comparison difference between the array flexible inclinometer and the manual inclinometer data is small, and the maximum difference is about 5mm. In the key position of the deformation area, the comparison data of the nozzle position is highly consistent, and the error is small.

4.2 The unique nozzle azimuth correction function of array flexible inclinometer has played an effective role in solving the problem of buried direction deflection of inclinometer, and the effectiveness and consistency of monitoring data has been well verified. It provides a new solution to the problem in the construction and embedding of inclinometer casing and pipe shape torsion.

4.3 Compared with manual acquisition method, automatic inclinometer scheme has great advantages in data acquisition frequency and timely data response. Array flexible inclinometer is fully applicable to long-term continuous and unattended monitoring projects, which can effectively improve the real-time and accuracy of monitoring response and reduce the risk of engineering construction.

Flexible Inclinometer Data Logger Monitoring Cloud Platform

__________________________________________________________________________________________________________________________________